Panasonic Ramps up EV Battery Production at Tesla’s Nevada Gigafactory

Japanese electronics giant Panasonic is boosting the production of electric vehicle (EV) batteries at the Nevada Gigafactory, jointly operated with Tesla, its leading consumer. This comes in response to increased demand from Tesla, who has pledged to purchase as many batteries as Panasonic can produce amidst a fiercely competitive EV market, reports Nikkei.

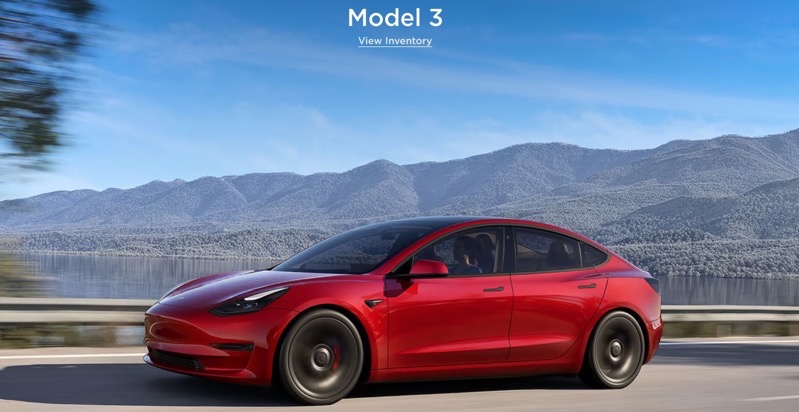

The battery production arm of Panasonic, Panasonic Energy, will reportedly set up a 15th production line at the Gigafactory. Expected to be operational within one to two years, this new line will enhance the annual production capacity at the facility by about 10%, increasing from 38 to 39 gigawatt-hours, which can power 500,000 to 700,000 Tesla Model 3 vehicles.

This production expansion follows Panasonic Energy’s announcement last year of a significant investment in a new battery plant in De Soto, Kansas. The company plans to quadruple its EV battery production by 2030, in a bid to stay abreast of the soaring EV demand.

Recent U.S. tax incentives aimed at boosting domestic EV and battery production under the Inflation Reduction Act (IRA) have also stimulated Tesla’s increased appetite for batteries. This policy could potentially lower the price of Tesla’s vehicles and support the production of battery modules.

The surging demand from Tesla has, however, prompted Panasonic to alter its initial plan for the Kansas plant. The company was initially set to develop a new type of battery known as the 4680, but has now switched its focus to the more familiar 2170-type batteries, as they can be produced at a quicker rate.

Despite the boosted production at the Nevada Gigafactory, Panasonic remains cautious about further expanding capacity there, as the U.S. EV market becomes increasingly crowded with major manufacturers like General Motors, Ford Motor, and new entrants such as Rivian, threatening Tesla’s market dominance.

Panasonic’s expanded production also aims to address the shortage of batteries for Tesla’s U.S.-manufactured vehicles. The current supply of batteries is anticipated to stay limited until Panasonic’s Kansas factory becomes fully operational in 2025. Analysts speculate that Tesla’s in-house 4680 battery production may not be progressing as expected, further stressing the need for Panasonic’s increased output.