Tesla Partners with Chinese Firms for 4680 Battery Parts: Report

Tesla has initiated the purchase of cathode coils from two secondary Chinese battery manufacturers, which apparently took place in the latter half of 2023.

These components are being shipped to Tesla’s Giga Texas factory in the United States for the production of 4680 batteries, as reported by the local media outlet LatePost (via CnEVPost).

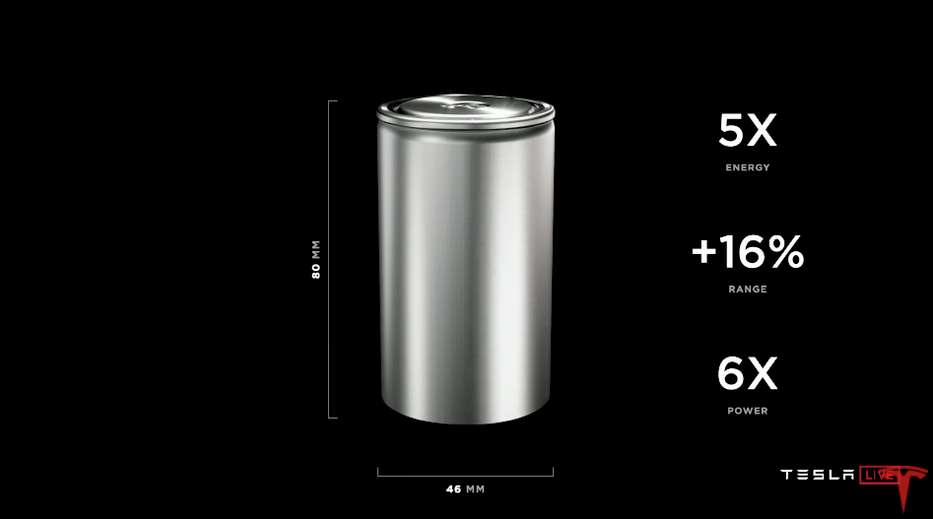

Cathode coils, crucial in battery cell manufacturing, account for approximately 35 percent of the total cell cost. These coils are part of Tesla’s strategy to expand the production capacity of its 4680 batteries, a design first unveiled during Tesla’s 2020 Battery Day presentation. The 4680 battery is Tesla’s first battery designed entirely in-house, with the potential to reduce costs significantly.

According to the report, Tesla had conducted audits of various Chinese cylindrical battery production lines last year, ultimately selecting these two suppliers for their cathode coils. The practice of sourcing these components from China is expected to continue into the third quarter of the current year.

An unnamed source close to Tesla revealed that Panasonic, Tesla’s battery supplier, is not anticipated to commence production of 4680 cells until the third quarter. Tesla had previously sought cathode coils from larger battery manufacturers, including CATL and BYD’s battery unit FinDreams, but was declined as these companies prefer selling complete cells.

The process of sourcing only cathode coils is uncommon due to the intricate and controlled environments required for cell production. Additionally, importing these coils from China to the United States incurs significant costs, given the need for high sealing in transportation, specialized packaging, and the urgency to transform these coils into cells within a short timeframe to avoid quality degradation.

Tesla’s move to import coils is part of its effort to surmount production bottlenecks and scale up the output of the 4680 battery. Despite the ambition to mass-produce this battery in 2021, Tesla only managed to commence small-scale production by mid-2023, contributing to the delay in the launch of the Cybertruck.

As of the reports, Tesla’s Texas factory reportedly has a limited production capacity, currently sufficient to supply only an alleged 24,000 Cybertrucks annually, far below Tesla’s initial projections. The company also faces the challenge of achieving dry coating for the anode but has not yet done so for the cathode, requiring the outsourcing of common cathode materials for battery production.