Inspecting the Tesla Model Y Body Structure [VIDEO]

image via Munro Live

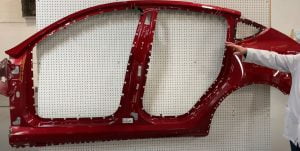

The Tesla Model Y continues to attract analysis and reviews from all kinds of different sources. In a new installment of Munro Live’s Tesla Model Y tear downs, viewers get a closer look at the electric vehicle’s body structure. Munro Live also delves into the vehicle’s hot-formed steel, the internal structure, and much more.

The video begins by showcasing the aperture of the Model Y. The video highlights the manufacturing process. To create the vehicle’s aperture, one piece of steel goes into a press. Sections are then stamped out to make way for the rest of the vehicle’s components. Because of the piece’s visibility, the aperture classifies as a Class A surface. The term refers to any surface that’s difficult to stamp.

A closer inspection of the rest of the body reveals thin strips of foam between components. Several weld nuts are also visible throughout the Model Y body. Many weld locations showcase two or three thicknesses, referred to as T2 or T3 welds, respectively. Such design features are present across many aspects of the Tesla Model Y, serving as another testament to the vehicle’s superior engineering build. Smaller spot welds on the top side of the body make for added strength. As explained, these more precise welds assist the vehicle with rollover, collisions, and intrusions.